PrintVis/ESKO PrePress Integration for Folding Carton

Introduction

This documentation is about a standardized JDF integration with predefined goals and results.

This integration provides two types of JDFs:

-

Prepress JDF

- For the basic creation of an approved, single-product PDF without step and repeat information.

-

Production JDF

- Full production PDF and dies layout creation for a full

production cycle.

This article is not about this functionality, as this is a 'normal' JDF transfer.

- Full production PDF and dies layout creation for a full

production cycle.

The integration can be used to communicate between the PrintVis administrator and the prepress department when new product comes in and work is needed in the prepress production.

PrintVis communicates with the ESKO Automation Engine via JDF and JMF files.

Sometimes this is for new products, and sometimes it is with updates on existing products, for example new artwork, changes of color. For more significant changes, a new product may be a better solution.

In PrintVis, product information is kept on the Item card, as products in PrintVis are referred to as Finished Goods items.

It means that the Item number is the equivalent of the Product number in ESKO.

There are certain settings on the Item card which keep information that ESKO will need to operate, and settings which help the PrintVis user navigate in the system to find out the current status of an item (product).

There are prerequisite setups on:

-

Basic JDF setup

-

General PrintVis Setup

-

CIM setup

-

The CIM Controller

-

A product group for Prepress jobs

-

Product group setup generally, setting a workflow

-

Order Type for Prepress jobs

When the prerequisite setup has been done, daily use of the integration can begin.

For basic JDF communication, please look at the dedicated article for this. CIM setup / JDF setup

The functionality of the standard workflow setup will contain:

-

JDF/JMF communication between PrintVis and Automation Engine

-

Status exchange via JMF in real time

-

Customer companies creation in WebCenter initiated from within PrintVis via JDF

-

User creation in WebCenter initiated from within PrintVis via JDF

-

Feedback from AutomationEngine to PrintVIS about inks, coverage, thumbnail, etc. (in preparation!)

-

Upload of customer files from PrintVis to AutomationEngine

-

Automated preflight of customer files and report

-

Creation of proof reports

-

Customer approval via WebCenter or email

-

Automated Step & Repeat from Layout JDF

-

Upload to plate suppliers FTP servers

-

WebCenter as approval tool and for exchanging products between sites

Two types of orders can be issued

In commercial printing, a typical standard JDF workflow is made for a fully integrated production order, where all production processes - from layout work in prepress to the packing of the final product - are included.

The workflows for the label, flexible packaging and box-producing

industries differ here, because the workflow starts with a separate

prepress order. The prepress order is used because these industries work

with so-called Finished Good items.

A Finished Good item is a defined product which could be reordered and

produced in the same way again and again. This means the prepress flow

and preparation is a generic process - and not related to a production

order.

ESKO Prepress Orders

The prepress order contains all information including the customer approval for the final product without step and repeat information. This kind of order is triggered from the PrintVis Item Card. There can be 1 or more prepress order for each item. Typically, if there is a layout or data change for a specific item, a new item will be created to make sure the production is not producing from an outdated layout.

The PrintVis Case is used for communication between PrintVis and AE. The data and status information are stored in the Item Card.

A Prepress order can also be used for "sampling" - so that costs from materials and modeling/sampling time can be recorded on a Case and included in our cost analysis of a product or a customer's activities.

ESKO Production Orders

The production order contains all information for the printing and die cutting processes, specifically for a certain press in production, where the product is placed with 2 or more apps in the printing section of the press with inline or offline die cutting. This layout for the printing section is called step and repeat.

The PrintVis Case is used for the communication and all technical information comes from the calculation structure in PrintVis.

PrintVis System Requirements for JDF/JMF integration

PrintVis requires the following Granules and tools for full JDF/JMF support:

-

PrintVis Manufacturing Integration License

-

PrintVis External WCF Communication Component (Windows Installer)

-

WCF Service Serial No.

Prerequisite Settings

PrintVis General Setup

In the PrintVis General Setup we have the option for generically adding a

certain order type and product group to the Case Card for the Prepress

order.

In this case, a product group called PREPRESS has been created, and an

Order Type as well.

These values can be used for searching, filtering and reporting later on.

Prepress setup fields: (for other fields please find additional information on the "PrintVis General Setup" article)

| PrePress Job Template Usage | Options are:

When selecting the Finished Good item on the case card, there is the option to choose a formerly created job instead of a template for the new prepress case. |

|---|---|

| Prepress Job Quoted Price =0 | In case you don't want to charge your customer for the initial Prepress PDF creation and other prepress work you can set this field to "True". The quoted price on the new prepress case will then be by default =0 and not calculated from the estimating parameters. |

| PrePress Product Group | Select the product group that is applied to the prepress cases/jobs. |

| Product Group Text | Description of the selected product group will be displayed. |

| PrePress Status Code Order | Select the status code that is applied to the prepress cases/jobs. |

| PrePress Status Code Description | Description of the selected status code will be displayed. |

CIM setup

The specific setup for this AE Integration begins on the PrintVis CIM Setup

This setup will create the initial Esko-related Item categories and make them available on Item cards.

Activate ESKO JDF Integration

The field Esko JDF Integration Active needs to be enabled.

CIM Controller Setup

Create and adapt a CIM controller for your ESKO environment:

| Field | Description |

|---|---|

Target URL

|

Set up the IP address and port for the ESKO Automation Engine Server in your network

|

| Esko Prepress Workflow | If you have a default Prepress workflow, you enter the name of it here. It must match the exact name of the Esko workflow. What you see here is the standard workflow. If you have more bespoke workflows in your Esko AE system, you can specify this on each item when they are created. This is done through the Item attribute. |

| Esko Production workflow | If you have a default Production workflow, you enter the name of it here. It must match the exact name of the Esko workflow. What you see here is the standard workflow If you have more bespoke workflows in your Esko AE system, you can specify this on each item when they are created. This is done through the Item attribute. |

CIM Device Setup

On the device that is used to process the Prepress Job, the setting PrePress Job Creation needs to be switched on.

Product Group Setup

A Workflow Partner Command of a Case/Job with this Product Group attached will be of the type "PrePress."

Set the field PrePress job.

This can be used if there are different workflows in ESKO per PrintVis Product Group.

PrintVis checks the Product Group workflows first - and if empty it will choose the workflow setup on the controller.

Result:

Lines of type Prepress in the Workflow Partner Commands.

Status Code Setup

Set "Send Job to Workflow Partner" = TRUE (Switched on)

If a Case Card is switched to this status, a Prepress Job command JDF

will be sent to Esko.

Esko will create a new Product with the information PrintVis has sent.

Cost Center / Configuration Setup

The ESKO AE needs information about the press brand and "ink set," in case it is a digital press.

On the Cost Center card, 2 fields are available for input:

These fields will be used and transported for production jobs.

| Field | Description |

|---|---|

| Esko Press Brand | If the actual Press brand is not on the list, then leave the field blank. Esko uses this information to slightly alter its workflow to cater to specific press brand requirements in the JDF which is output to the press from Esko. A blank value will simply not have any alterations and be perfectly normal. |

| Esko Print Process | If applicable to the current printer, pick either offset or digital. If none of these options apply, leave blank. |

On the Cost Center Configuration, the Esko Ink Set can be chosen:

Ink Set options are:

These choices are aligned with the setting in your current Esko system - they will know what to select.

Item Card

The Item Card is a placeholder for the most recent information about this product.

Information is kept in the existing Item Card fields, but also in the Item Attributes.

It is OK when not all information is available, we will transport what we have.

Of course, the more complete our information is, the better for the automation of the job processing. See more of the procedures below.

Fields on the Item card:

In the Item Card, information is kept in the following fields:

| Field | Description |

|---|---|

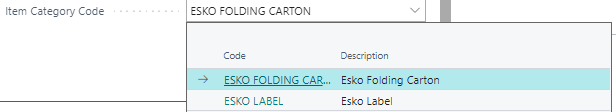

| Item Category Code | If you have added the extension for ESKO integration, you will have a couple of options here. You may be printing labels, folding carton boxes or even both. For each new product/item you will give them an Item category. This is not for raw materials or any type other than ESKO products. For a box product, pick Folding Carton  |

| Item Type | Finished Good |

| Item Description | Product description |

| Format 1 | The gross width of the flat 1-up layout, in the unit which is used in the PrintVis database setup (if you are working in imperial units, then this measure is in inches, if you are working in metrics this is in cm or mm, depending on your Standard Unit choice). This must match the artwork PDF which is made for this product. |

| Format 2 | The gross length of the flat 1-up layout, in the unit which is used in the PrintVis database setup (if you are working in imperial units, then this measure is in inches, if you are working in metrics this is in cm or mm, depending on your Standard Unit choice). This must match the artwork PDF which is made for this product. |

| Paper Item no. | The paper Item number on which we intend to print the product. |

| Colors front | The number of colors printed on the front side of the flat unfolded box. |

| Colors back | The number of colors printed on the back side of the flat unfolded box. |

| Sell-to no. | The customer number for whom you are making this product/item. If this is an internal job (our own house boxes) then create a ‘house’ customer. It will be useful in filtering later. |

Example item setup:

Creating a Prepress Case

This chapter only describes the prepress order creation and the related JDF which is ESKO-specific.

From Case Card

-

Create a Case as usual and select a Product Group that is set up for PrePress jobs.

-

Select a Finished Goods item

- A dialog pops up

-

Yes: The template from the Item or Product Group will be copied and created as a new job on this case.

- See PrintVis General Setup

-

No: Existing jobs that have been created for this Item no. will be listed to copy and create as an existing job for prepress case.

-

A JDF will be created and sent to the Esko Automation Engine when changing to the ESKO prepress Status code

-

The Item Attributes will be exchanged and updated by the JMF respond from ESKO.

A new job (the copy of the selection above) is now added to the case, enter a job name and the case is now ready for further use.

The attributes FactBox of the finished goods item can be selected to be displayed as FactBox on the Case Card as well. It mainly stores information relevant to a JDF integration.

The Item Card of the selected item can be directly opened by the case card action: "Finished Goods Item."

From Item Card

In the Item Card there are Actions to create a new PrePress case, as well as the option to view existing PrePress cases for the Item.

Send a JDF

Just change the status to the PrePress Status Code that has the setup "Send Job to Workflow Partners = "TRUE""

Result in PrintVis

Result in ESKO

Product

Jobs

Prepress job Scenarios:

Within the Prepress job creation, we are operating with a small list of

different scenarios, which could be anticipated and with which we know

how to communicate to ESKO Automation Engine.

Esko Automation Engine has a range of predefined, automated workflows

which we are triggering as we are sending JDF files with information.

-

Create New AE product and initiate a new Prepress Job for this.

This is the minimum level.

A Finished Goods item is created in PrintVis by a PrintVis user.

Information are entered (what is known) by the PV user.

User creates a Prepress Job in PrintVis, changes to a status code which creates the JDF file and sends to ESKO Automation Engine. -

Update of created AE Product and/or Prepress Job with more information

If more information comes to the PV User, this is entered on the FG item card.

User can now create a new Prepress job (if the old one has now been closed) and put in relevant status doe.

This will update the product in ESKO AE and initiate an additional workflow. -

Upload a 1-up CAD file from external source to existing product.

The PrintVis User has received a CAD (1-up) file from an external source.

PV User manually places this in a folder, reachable from the AE server.

PV User creates a new prepress job or picks the existing one. In both cases, moves to relevant status code.

The will cause AE to find and import the CAD file from where it was placed.

AE workflows will check and error out if the information in the CAD file is not matching up to previously given information, or if it did not find the file in the destination given by PrintVis. -

Upload a PDF art file from external source to existing product.

The PrintVis User has received a PDF art file from an external source.

PV User manually places this in a folder, reachable from the AE server.

PV User creates a new prepress job or picks the existing one. In both cases, moves to relevant status code.

The will cause AE to find and import the PDF file from where it was placed.

AE workflows will check and error out if the information in the PDF file is not matching up to previously given information, or if it did not find the file in the destination given by PrintVis. -

Combinations: Various combinations where the Item details and attributes in PrintVis are filled, including file placements, and a prepress job is created.

At any point after the product has been created in Automation Engine, more information can be added to the Finished Goods items and be updated through the prepress job JDF launch.