Status Codes

Summary

Status Codes are an integrated tool in PrintVis which directs the workflow of a case through the company on a general level; controlling whether, for example, you may register job costing, plan, invoice, etc. Also, on selected points, it controls whether a case has been created correctly before it changes status, etc. Naturally, it is important to consider how you want to control individual cases when you set up the company's status codes. You must also consider the demands made on the case and what a case is allowed in each individual status.

When the company's status codes have been created, you must also set up a natural status flow and set up who is to be responsible for a case when it reaches a given status. This is done in the Responsibility Areas window.

Status codes are available to all users by default, but if you want to limit a user to only be able to change to a select few status codes, that is possible in the menu of the PrintVis User Setup page:

Setup

The Status Code Setup can be found by searching "PrintVis Status Codes".

General Tab

| Field | Description | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Code | Code is the identification field for the Status Code. Length is max. 20 characters. | ||||||||||

| Text | Status Code name | ||||||||||

| Description | A meaningful description that explains to the user what this is. | ||||||||||

| Deadline Period | It may be an advantage to control the Deadline field on the Case card, so that when a case changes to a given status, the system must automatically suggest a deadline which is not today. In this field, you can set up a date formula for calculation of a new deadline that will be calculated when changing to this status code. For example:

|

||||||||||

| Next Status | By a look-up in the field, you open the list of Status Codes. Here, you choose which status must be suggested as Next status in a standard sequence. You can also define this in Responsibility Areas setup. | ||||||||||

| Sorting Order | If you indicate a numeric sorting in this field, the Status Codes are presented in the list within each Order status, sorted by the entered value. | ||||||||||

| Priority | Here, it is possible to award a Priority to this status. This is used in Case Management as a filter and sorting. | ||||||||||

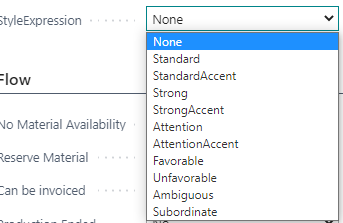

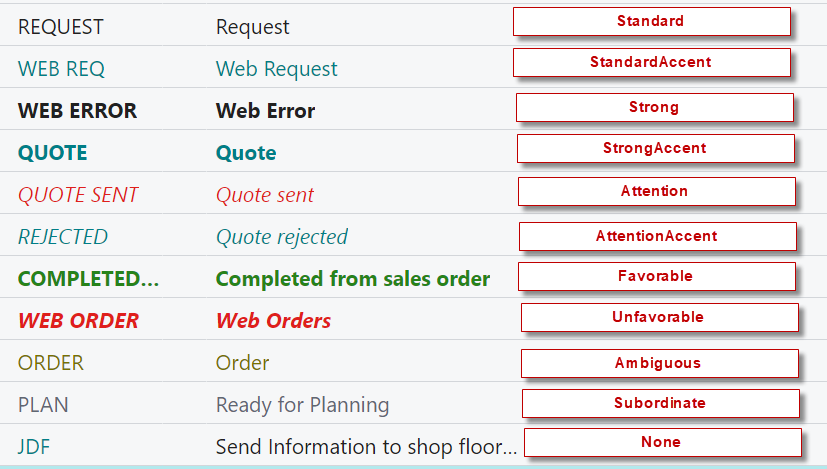

| Style Expression | This field allows for the status to appear differently in the case

list. Possibilities are:  Examples:  |

||||||||||

| Show in Case Management | Select this field if you want to be able to be able to view cases with this status in the case list. This only impacts the Matrix, which is setup on the PrintVis User Setup page in the Timeline field (when selecting Status Code value). | ||||||||||

| Show in production plan | Select this field if cases with this status are to be presented in the Production Plan Page. The case will still be visible on the Planning Board and, if a start date exists, it will be also visble in the shop floor production plan. |

||||||||||

| Editable | 2 options are available:

|

||||||||||

| System Status | Please note, during creation, a case cannot change to a lower Order status. This means you cannot change from a code where Order status is Order to a code where Order status is Quote. System Status can be one of the following options:

|

Please note: PrintVis requires a status code to start from in case there is some automation setup or from a role center a case of type order should be created.

Please make sure to always have a status code in "Request" status, with the lowest sorting number. You don't have to use that for your workflow or select it in a setup anywhere, but it must exist! Otherwise, a case could be created directly in Order status from a quote number that is pulled as well.

Flow Tab

In the Flow tab, you set exactly what a case may and may not do in the status in question. You have a number of options and for each one you may choose:

| Option | Description |

|---|---|

| No Change | This is the system default setting for all points in connection with the creation of new Status codes. The choice indicates that no changes have occurred compared to the status which a case comes from. Thus, it is important to select Yes or No precisely for all points on all Status Codes which a case may start in or move directly to. |

| Yes | Means that you may do what the heading indicates - see below. |

| No | Means that you may not do what the heading indicates - see below. |

| Field | Description |

|---|---|

| Remove Material Requirements | The field is used to control exactly when material may be purchased for an order. Yes - material requirements do not appear in purchase management. No - materials are available for purchase. As the default setting, the purchase of materials takes place at the time when a case reaches Order status but, via this option, you may adjust when the purchase may be made. |

| Reserve Material | Enter when materials for an order shall be reserved in the system. At default, this will automatically happen when the order status reaches “Order” but by selecting “No” in this field, you can choose to wait until the case reaches another status. |

| Can be invoiced | You may not post sales invoices for the Order until Yes has been

selected. Typically, you will want to make sure that the Job costing

has been carried out and that status has changed to, for example, "Ready

for invoicing" before you allow invoicing. Some companies also need to be able to invoice on account and they often set up a special Status Code for this purpose. |

| Production Ended | Normally, you select Yes to whether an Order is ended when the case reaches a status where the Production is completed. All planning units from this job now are marked as completed. Posting consumption on this job is still allowed. If you have selected Automatic Job costing in the setup, this is done when a case is marked Completed. When a case reaches a status with Production Ended = Yes, the Production Completed DateTime on the case is filled in. |

| Can be planned | Not until the case reaches a status marked Yes, the system creates Planning units for an Order. |

| Proof approved | This is a special function which is used only in connection with JDF. A Status Code with selected YES must be assigned to a planning unit, indicating at such status, proof is automatically regarded as approved by the customer. (See also JDF Setup) |

| Job Costing may be registered | If you select Yes, you may perform job costing for an Order. Typically, you may not perform job costing until a case reaches Order status Order. |

| To be Archived | When a case is terminated and invoiced, you typically want it to be transferred to the case archive. If you select Yes in this field, the order is filed and if nothing else is set up, the order receives a Statistics date when it reaches a status where it is filed. |

| Allow raw material picking | If you select Yes, items may be released from the inventory for an Order. Often raw material pick is not possible until a case reaches the Status code Print as only paper must be released from the raw material inventory. |

| Canceled | Sometimes an Order is cancelled. To be able to create statistics on how many cases are cancelled, many choose to create an individual Status Code for this purpose. In connection with this status, it may be a good idea also to set up a check of whether job costing but not invoicing has been performed on the order - see the section on Requirements. |

| Request Complete | When a status code with this checked is reached, the Request Completed DateTime value is filled in on the case. |

| Estimate Complete | When a status code with this checked is reached, the Estimate Completed DateTime value is filled in on the case. |

| Flow Data | |

Department Cost Center |

By selecting either a Department or a Cost center (or a combination of both), you may choose that all Orders with this Status Code are to be displayed in the Production list of employees logged into the selected department and/or the selected Cost center. |

| Auto Job Costing | If this field is ticked, the system will automatically flush the

costs for any time and material in the estimation (calculation lines)

which have a Unit of Measure set up for back flushing. The system will look at each line, examine the Unit of Measure, and, if eligible, create a job costing line with the estimated quantity and the cost & pricing as per the Unit of Measure setup. |

| Create Sales Invoice | Automatically create the sales invoice when the order reaches this status. |

Version Management Tab

Via the Version management tab, you may use Status Codes to control which job versions may be edited when a Case reaches the status in question.

If a field is selected, the version in question may be edited.

It is often efficient to establish that Request and Quote version may not be edited when a case has become an Order. Or that, for example, Request, Quote and Order versions may not be edited when a case has become a Production order.

Finally, you may choose that only active versions may be edited. This may prove a great advantage, for example, in the quote stage where there may be different quote job items. Thus, you can make sure you are working on the correct case, so you do not overwrite other versions of the quote by mistake.

Integration tab

| Field | Description |

|---|---|

| Prod = Sale | In the Sales order integration section, you may select the field to ensure that if a sales order changes status to the indicated Status Code, this automatically entails that the corresponding Production order gets the same status or vice versa. This means that the field is only used if you actually use Sales/Production order integration. |

| CRM integration | Here, you can select an Interaction Template. This is the connection to Relationship Management from Standard 365 Business Central. |

| CIM | Send Job to Workflow partners, Notify Workflow Partners, Workflow Partner Notify Format |

| Purchase Integration | Create Paper Purchase Documents |

| Create Folders | The system creates empty Case Folders based on PV Folder Group Setup. |

| Delete Empty Folders | The system deletes empty Case Folders at this status. Note: If you have the "Delete Empty Folder" function on a Status Code which is not ARCHIVE and then click on open "Folders" at the Case Card, the Folders will be recreated. Only on status ARCHIVE (this function must be on here) will the deleted folders not be recreated. |

| Document Management | In the Document Management section, you may use a look-up in the Standard document field to select that the system must automatically generate the selected document when a case is assigned this Status Code. The document is not printed but is created and ready to open and print. In the Standard document name field, you may, if necessary, set up a standard document name based on the same principles as in the document setup window in the document management tool. |

| eCommerce | Customer job tracking, External Status Description |

System Status Tab

| Field | Description |

|---|---|

| Default Quoted | If you print a report, set up under the Quote section in the Report setup, from Graphic Production Order, status changes to this Status code when the report has been created. In Graphic case card/the Info tab, you checkmark the field Quote printed on when you print and this checkmark may move status forward to this Status code. |

| Default Quote Rejected | When using BC CRM Opportunities, this is the status code that is used when marking an opportunity as lost. |

| Default Ordered | When using BC CRM Opportunities, this is the status code that is used when marking an opportunity as won. |

| Default delivered | When all shipments for a Graphic Production Order are marked shipped, the order is moved to this status code. |

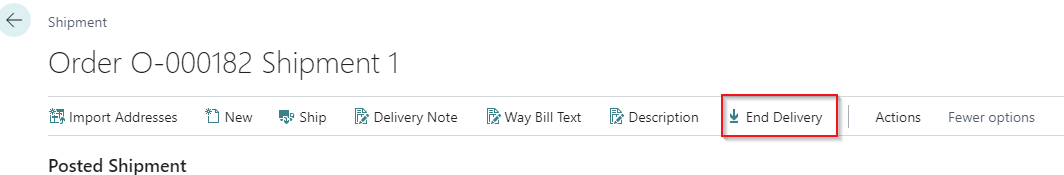

| Default fully delivered | If this is checked on any status, the End Delivery action appears on the shipment card. Using the End Delivery action to mark the shipment as shipped completes all shipments and moves the case to this status code.  |

| Default Invoiced | When an invoice is posted on the Graphic Production Order, the order is moved to this Status Code. It is most often used for Status Code Archive as a case is most often to be filed when it has been invoiced. |

| Order WIP | This function is only used in connection with system start-up. By selecting the field of a specific status code (with Order status Order), you may allow the users to assign the old order number to these orders when they create orders WIP from a previous system. The checkmark in this field should be removed immediately when all orders WIP have been created and the status code should be blocked. |

| Blocked | If you want a Status Code to no longer be available, select this field. Naturally, you may still work with cases which currently have the status in question, but the Status Code cannot be assigned to new cases. |

Requirements Tab

Via the requirements tab you may set up a number of check points per status code. Common for all points is that the check is performed in connection with a case changing to the selected Status Code. In connection with each option, you may make one of 3 choices:

| Option | Description |

|---|---|

| Blank | Is regarded as not filled in - so no check is performed. |

| Warning | If the desired check is not filled in, the user is warned about what needs to be filled in, but the case changes status to the selected Status Code. |

| Stop | If the desired check is not filled in, a message is sent to the user about what needs to be filled in, and the case stays in the present status. |

| Field | Description |

|---|---|

| Check Eco label | The system checks whether the Eco-label field on Case card is filled in. |

| Check Credit Limit | The system checks whether the customer's credit limit has been exceeded. If the Credit limit field is not filled in on the customer card, this is regarded as empty and the check is not activated. |

| Check Null Prices | The system checks whether there are any calculation details where quantity or hours are filled in but where the Cost and/or Sales prices are priced at 0.00. Please note: If the cost/prices have been manually set to 0.00, this check is not carried out! |

| Check Salesperson | The system checks whether the Salesperson code field on Case card is filled in. |

| Check Coordinator | The system checks whether the Order planner field on Case card is filled in. |

| Check Delivery Date | The system checks whether the Requested Delivery Date field on Case card is filled in. The field is either filled in on the Job line or via the Job window. |

| Check Reason for Rejection | The system checks whether the Rejection Code field on Case card is filled in. It is typically used for the Quote rejected or Cancelled Order status codes where it may be interesting to find out why you did not get the order or why it was cancelled. |

| Check Order Type | The system checks whether the Order type field on Case card is filled in. |

| Check Product Group | The system checks whether the Product group field on Case card is filled in. |

| Check Invoiced if Job Costing Exist | The system checks whether a Sales invoice has been posted if there is job costing on the case. This is meant to ensure that you do not File or Cancel cases where there is job costing without this job costing being invoiced. |

| Check Manual Prices | The system checks whether there are calculation details where the Cost or Sales price has been overridden manually. Only use this check if the system is set up to automatic calculation throughout, also in the case of any sub-contracting. |

| Check Condition Reference | |

| Check Condition Sets | As an extra check that certain things are in order, it is possible

to set conditions for certain parts of the estimate. The Status Code

can then be set to run through these conditions and throw an error to

the user if these are not met or are violated. There is a separate

whitepaper available regarding the condition setup. The field "Check Condition Reference" will enable you to point out just 1 of the condition sets to be checked at the status code change. If this field is blank, all condition sets will be checked. This function can serve as an alternative to the Status Code report for estimation checking purposes. |

Report Before Report After Report Before (Sales Doc.) Report After (Sales Doc.) |

If the above-mentioned check options do not meet a specific need of your company, it is possible to have a report developed which is activated when the status in question is reached. As such, there are practically no limits as to what may be checked via a report but, of course, it is necessary to have a clear definition to be able to develop the report for the company. |

User Specific Status Codes

PrintVis provides the possibility to limit status codes per user. On each PrintVis User, a set of status codes can be selected from the existing status codes. With such setup, it is only possible for the given user to work on a limited workflow and the user cannot change to status codes other than the ones selected in the PrintVis user setup.

This could be used if a user should not be able to create orders or quotes. For more details, check the article about the PrintVis Users